產品介紹

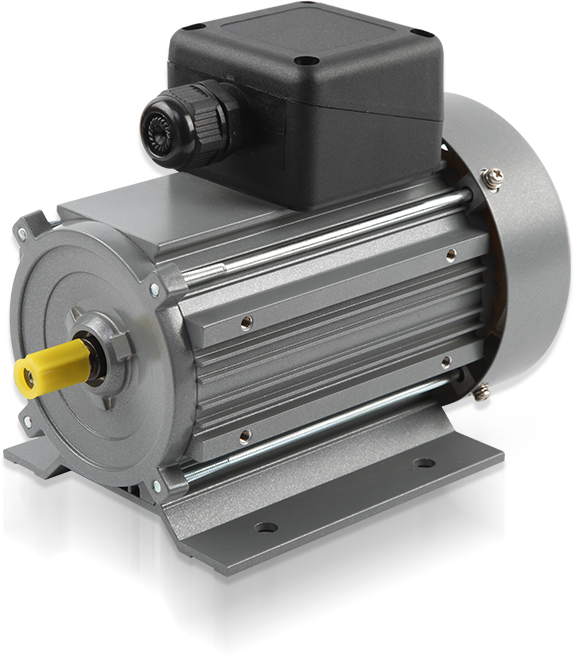

研深擁有十餘年客製化無刷馬達技術經驗優勢,專注於將傳統馬達升級為高效率客製化無刷馬達,特殊訂製的無刷馬達規格不僅為客戶提升了機器的應用範圍,同時也提升了客戶產品的品牌價值。客製化無刷馬達的應用不僅提升了整個產業的價值鏈,還幫助客戶的產品在競爭激烈的市場脫穎而出,獲取更多的市場份額。研深的客製化無刷馬達產品廣泛應用於各行業。包括家電產業的抽油煙機、電風扇和空氣清淨機等。運動產業的跑步機和划船機等。木工產業的集塵機、刨木機、鑽床、車床、磨床、台鋸及修邊機等手持可攜機械。金工產業的帶鋸機、銑鑽複合機和倒角機等,以及工業用的高壓噴霧機、攪拌機和工業風扇等。所有產品均與世界領先品牌共同設計開發,充分展現研深在技術創新與合作開發上的實力。

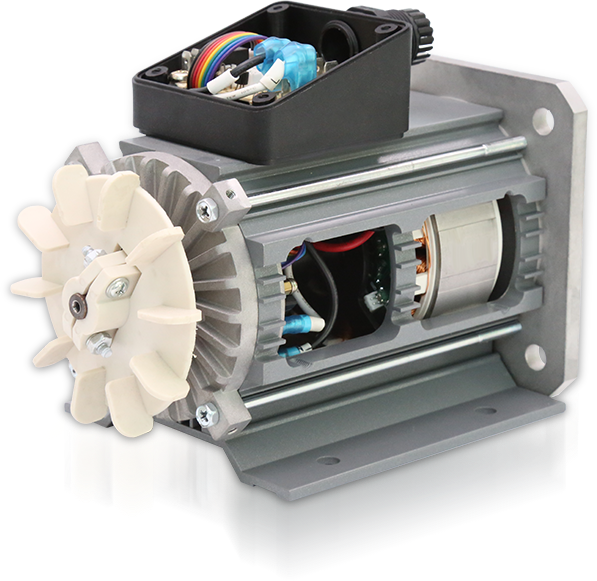

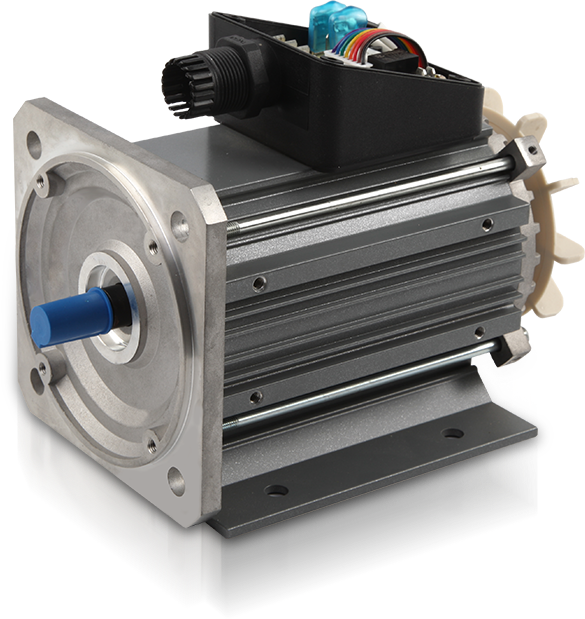

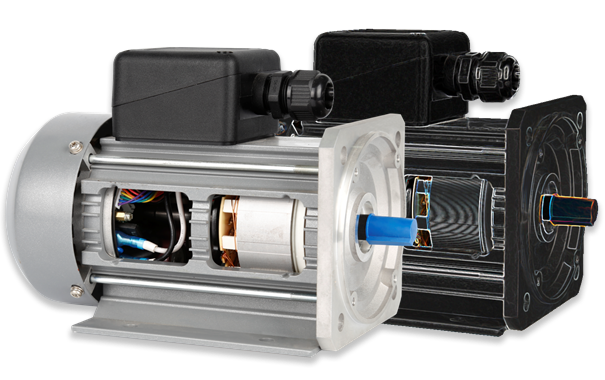

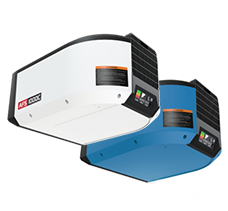

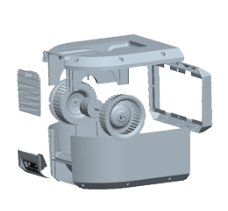

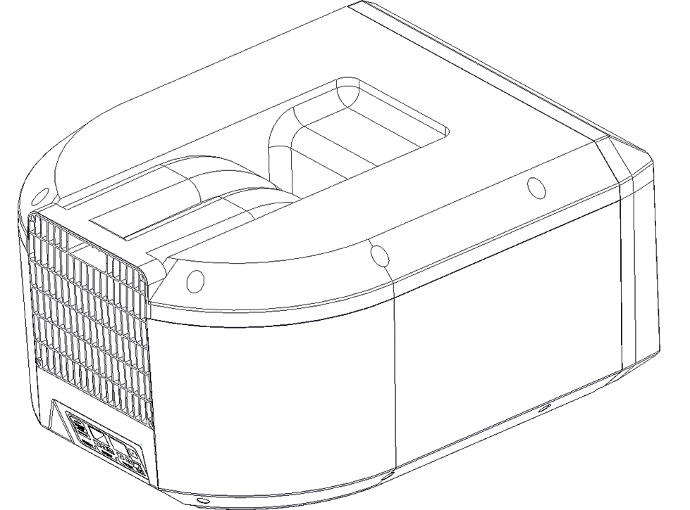

研深創造了全球首款內建驅動器且具有專利設計的緊湊型直流無刷馬達,功率範圍從1/8 HP到5 HP適用於各種應用,並獲得CE、UL、CCC、ROHS以及高效能馬達等最嚴格的認證。整合的一體化設計不需要額外設置電控箱,使得維護和故障排除更容易。我們可以客製化任何訊號輸出來實現機器智能化,包括急停開關、轉速調整、燈光輸出、故障訊號以及正反轉切換等等。此外,無刷直流馬達在低轉速下提供高扭矩輸出,並具有高效能、節能、體積小和運轉安靜等優勢。

直流無刷馬達解決方案

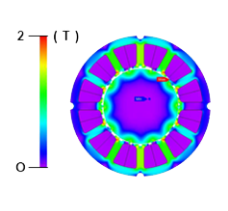

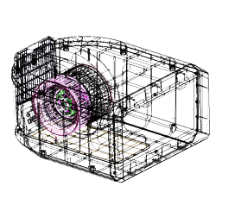

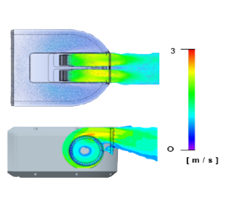

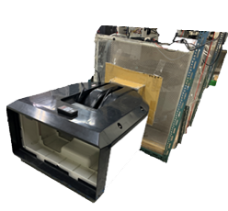

研深專精於客製化直流無刷馬達,並將馬達技術延伸至機器設計代工,突破傳統馬達的限制,顯著提升機器的節能效果、智能化與安全性。我們的產品開發流程獨具特色,從了解客戶需求開始,電腦輔助深入分析馬達動力核心,結合十多年來經驗開發最適配的控制器,並通過精密的機構設計與電腦模擬驗證,確保產品性能達到最佳標準。我們的開發流程顯著縮短了開發時間,避免了因選錯馬達規格而導致機器加工能力不足的風險。我們無須購買功能複雜且昂貴的變頻器來搭配傳統馬達,也無須花費長時間來調整變頻器和馬達匹配性。我們多年的專業確保機器在最適配的直流無刷馬達和驅動器下發揮最佳性能,使產品更加高效和經濟,為客戶節省開發費用和時間。

產品開發

馬達設計模擬

機構設計優化

電腦輔助性能模擬驗證

打樣組裝驗證

動力測試與性能實測

量化生產