Demonstration

Traditional induction motors are bulky and energy-consuming, leading to diverse product models and high inventory pressure.

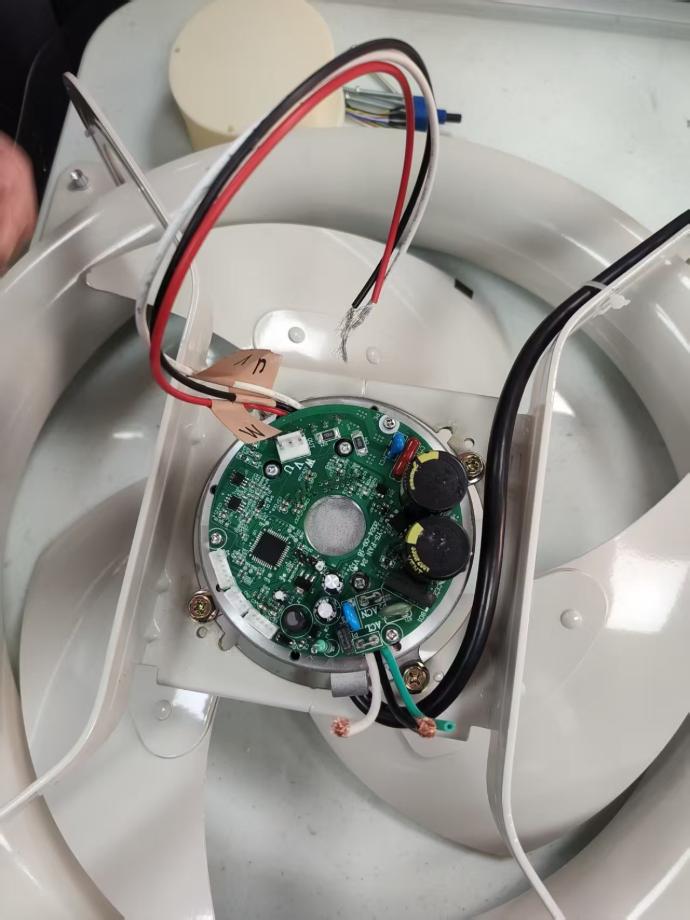

We assisted our customer in switching to brushless DC (BLDC) motors. By optimizing winding design, magnet grade, and the current-handling capacity of controller components, we achieved the following results:

Solution

- Adopted BLDC motors with a standardized frame size to replace multiple induction motor models

- One BLDC motor replaced two to three different frame sizes of induction motors

- Greatly improved parts commonality, effectively reducing inventory and management pressure

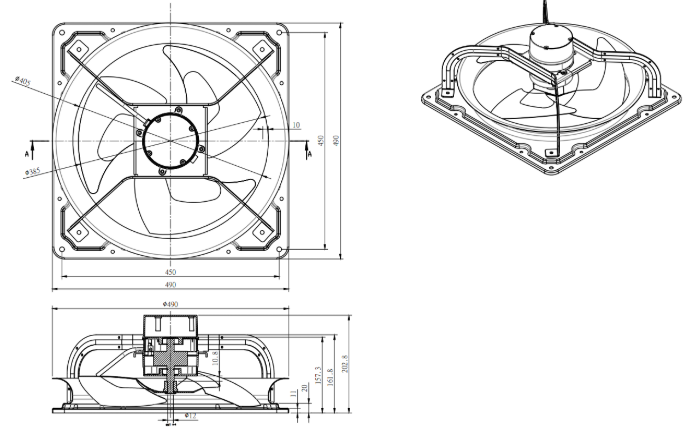

Real-World Application: Ventilation Fans in the Planting Industry

- Customer originally used 200W induction motors (1800 rpm)

- After switching to BLDC, power consumption dropped to just 85W—more than 50% energy savings

- Further optimization of winding and controller allowed the same BLDC motor to support both 200W and 400W models

Summary of Benefits: Clear, Data-Driven Results

| Item |

Improvement |

| Energy Efficiency |

Power consumption reduced by 55% |

| Parts Commonality | Two models now share the same set of components, significantly easing inventory pressure |

| Size & Weight | More compact, 30% lighter—easier to transport and install |

| Cash Flow | Inventory funding requirements cut in half |

| Production Efficiency | Faster assembly and parts preparation—production time shortened by 30% |

| Cost Reduction | Centralized procurement lowered unit prices and overall cost |

| Warehouse & QC Optimization | Fewer components, faster inspection, more precise warehouse management |

This is not just about energy savings—it’s a comprehensive upgrade in efficiency and cost optimization.

Why Choose YENSHEN?

Expert Engineering Support: Tailored motor solutions for every application

Reliable, Stable Quality: Stringent quality control for long-term operation

Proven Industry Experience: Decades in ventilation design with field-proven results